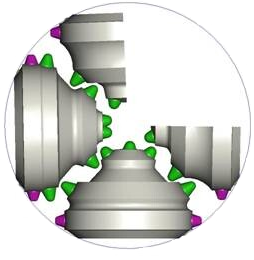

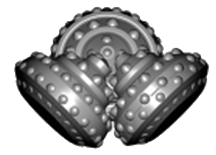

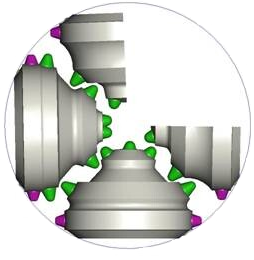

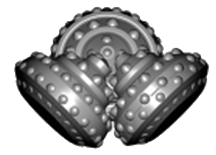

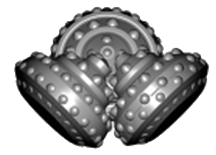

The PDB Tools mining TCI Tricone – GX Series bit is utilized for blasting hole open pit mining. Depending on the different formations of customers, we can offer different product with IADC from 40 to 80 types. Available sizes range from 6 3/4″ to 13 3/4″.

Through extensive ongoing Research & Development programs, PDB Tools incorporates the latest in materials, manufacturing processes, and engineering innovation to continually refine and improve our product line.

To increase the bit service life and the reliability, premium bearing designs of our bits have the best bearing configuration to maximize the bearing capacity.

Depending on different formation, specially selected carbide grade with the premium cutting structure designs balanced the load taking of the bits, insure the customers will have the best penetration rate in different applications.

Our products also can be customized to meet different customer requirements and applications.

| TCI, Roller-Ball-Roller Bearings, Jet Air Flow |

| GX40 |

Soft |

70-140 |

1000 to 4000 |

Cutting structure: Large diameter, long projection and widely spaced scoop, chisel, or conical inserts. Designed for maximum penetration in soft formations.

Features: Premium roller-ball-roller bearings and tungsten carbide thrust buttons, with maximum bearing capacity and air flow.

Application: Soft formations such as silt stone, shale, and soft limestone with 1,000 to 15,000 psi compressive strength.

|

| GX50 |

Soft to Medium |

50-140 |

2000 to 5000 |

Cutting structure: Long projection and moderately spaced chisel or conical inserts. Designed for high rates of penetration in soft to medium hard formations.

Features: Premium roller-ball-roller bearings and tungsten carbide thrust buttons, with maximum bearing capacity and air flow.

Application: Soft to medium hard formations such as shale, sandstone, medium granite, and certain marble with 10,000 to 35,000 psi compressive strength.

|

| GX60 |

Medium to Hard |

50-110 |

3000 to 6000 |

Cutting structure: Medium projection and densely spaced conical or bullit inserts. Designed for high rates of penetration in medium to hard, and abrasive formations.

Features: Premium roller-ball-roller bearings and tungsten carbide thrust buttons, with maximum bearing capacity and air flow.

Application: Medium to hard, and abrasive formations such as hard shale, hard limestone, quartzite, and basalt with 25,000 to 50,000 psi compressive strength.

|

| GX70 |

Hard |

50-90 |

3500 to 7500 |

Cutting structure: Short projection and densely spaced conical or bullit inserts. Designed for high rates of penetration in hard and abbrissive formations.

Features: Premium roller-ball-roller bearings and tungsten carbide thrust buttons, with maximum bearing capacity and air flow.

Application: Hard and abrasive formations such as hard quartzite, taconite, and banded ore with 35,000 to 60,000 psi compressive strength.

|

| GX80 |

Extremely Hard |

40-80 |

5000 to 8000 |

Cutting structure: Minimum projection and densely spaced round top inserts. Designed for tough drilling applications in extremely hard and abrasive formations.

Features: Premium roller-ball-roller bearings and tungsten carbide thrust buttons, with maximum bearing capacity and air flow.

Application: Extremely hard and abbrasive formations such as very hard chert, quartzite, and hematite ore with 50,000 psi and harder compressive strength.

|

Available Sizes

| 6 3/4 |

171 |

GX542 |

Soft to Medium |

3 1/2 |

|

| GX612 |

Medium |

3 1/2 |

|

| GX712 |

Hard |

3 1/2 |

|

| 7 7/8 |

200 |

GX432 |

Soft |

4 1/2 |

|

| GX542 |

Soft to Medium |

4 1/2 |

|

| GX612 |

Medium |

4 1/2 |

|

| GX712 |

Hard |

4 1/2 |

|

| 8 3/4 |

222 |

GX632 |

Medium to Hard |

4 1/2 |

|

| 9 |

229 |

GX432 |

Soft |

4 1/2 |

|

| GX542 |

Soft to Medium |

4 1/2 |

|

| GX642 |

Medium to Hard |

4 1/2 |

|

| 9 7/8 |

251 |

GX432 |

Soft |

6 5/8 |

|

| GX532 |

Soft to Medium |

6 5/8 |

|

| GX712 |

Hard |

6 5/8 |

|

| GX742 |

Hard |

6 5/8 |

|

| 10 5/8 |

270 |

GX432 |

Soft |

6 5/8 |

|

| GX532 |

Soft to Medium |

6 5/8 |

|

| GX632 |

Medium to Hard |

6 5/8 |

|

| GX712 |

Hard |

6 5/8 |

|

| GX722 |

Hard |

6 5/8 |

|

| 11 |

279 |

GX532 |

Soft to Medium |

6 5/8 |

|

| GX642 |

Medium to Hard |

6 5/8 |

|

| 12 1/4 |

311 |

GX532 |

Soft to Medium |

6 5/8

BECO |

|

| GX642 |

Medium to Hard |

6 5/8

BECO |

|

| GX722 |

Hard |

6 5/8 |

|

| 13 3/4 |

350 |

GX532 |

Soft to Medium |

6 5/8 |

|

|